What is the stainless steel ferrule connector and its working principle?

Time:

2022-11-23 13:59

The stainless steel ferrule joint is a new type of pipe connecting element, which is applicable to the pipeline system of oil, natural gas and general corrosive medium, and the working pressure is 16-40pma. The stainless steel ferrule type joint structure mainly consists of ferrules with 24 ° tapered holes, sharp inner edges and nuts with compression effects. Push the ferrule into the 24 ° taper hole of the joint, tighten the nut, make the edge of the ferrule cut into the steel pipe of the stainless steel ferrule joint and form a circular groove, and then play a sealing role.

The stainless steel ferrule connector has the characteristics of reliable connection, convenient installation and maintenance, good sealing, high pressure resistance, high temperature resistance, good repeatability, safe and reliable work, etc.

working principle

The stainless steel ferrule joint is to insert the steel pipe into the ferrule, lock it with the ferrule nut, collide with the ferrule, cut into the pipe and seal it. It is unnecessary to weld when connecting with the steel pipe, thus eliminating the malpractice caused by careless welding. It is applicable to the fields of fire prevention, explosion prevention and high-altitude operation. Therefore, it is applicable to the connection of oil, gas, water and other pipelines. It is one of the more advanced joints in the pipeline of automatic control devices of natural gas, food, petroleum, pharmacy, instrument, oil refining, chemical and other systems.

Stainless steel ferrule connector has the following advantages:

1. Simple structure, reliable sealing performance, convenient use, excellent manufacturing, light weight and beautiful appearance.

2. There is no need to add gaskets or weld, and it has good performance of repeated assembly and disassembly.

3. Because no welding is needed, it reduces the impact of pipeline impurities on system performance. Therefore, stainless steel ferrule joints are more and more widely used in the occasions with combustion risk, high-altitude operation and frequent disassembly and assembly.

Assembly method:

The performance of stainless steel ferrule joint is not only related to the material, manufacturing accuracy, heat treatment, etc. of the parts, but also related to the assembly quality. Therefore, the assembly shall be carried out as follows.

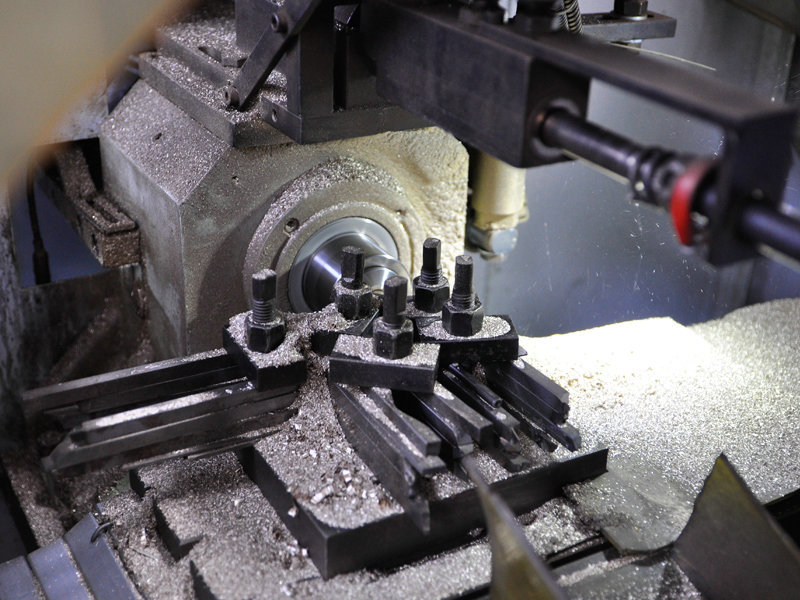

1: Cut the pipe according to the required length on the special machine tool or manually. The perpendicularity between the cut surface and the centerline of the pipe shall not exceed half of the external tolerance of the pipe.

2: It is necessary to remove the internal and external burrs, metal chips and dirt at the pipe end.

3: Remove rust preventative oil and dirt from all parts of the pipe joint.

4: Put the nut and ferrule on the pipe in turn, and then insert the pipe into the bottom of the tapered hole of the connector body. When tightening the nut, turn the pipe until it does not move, and then tighten the nut 1/3 turn.

As the stainless steel ferrule joint is made of stainless steel, it can prevent rusting due to time problems to a certain extent and reduce certain damage. At the same time, it has the characteristics of corrosion resistance and simple installation, and to a certain extent, it meets the requirements for dry materials in chemical, petroleum, pharmaceutical and other fields. In addition, stainless steel ferrule joint requires certain installation skills during installation, so we need to operate on the basis of understanding its composition and application principle. I hope that the above explanation of stainless steel ferrule joints can play a role in your installation.

Recommended information